Your Premier Wet Grinding & Dispersing Partner

Explore Our Range of Bead Mills, Dispersers, Tanks, and Custom Production Lines Tailored to Your Unique Requirements.

- Bead Mill Machines' Expert Since 1993

- Increased Energy Efficiency by 20%~30%

- Achieving Grinding to Nanoscale Precision

- Safe, Efficient and Professional Design

Intro and Form

Discover the Difference Reach Out to Us Today!

Wet Grinding Experts Since 1993

Since 1993, Allwin has pioneered in wet grinding technology. Founded by Mr. Wang Yongqi, who contributed to China's first bead mill, we're proud of our legacy in transforming grinding technology. With over 10,000 units sold and a global presence, we're leaders in our field.

Innovative Nano Milling Technology

Our advanced bead mills, powered by Nano Milling Technology, are designed for precision. We grind materials down to nano sizes, meeting stringent industry standards with unmatched accuracy.

Energy Efficiency Redefined

Achieve greater energy savings with our bead mills. Engineered for 30% higher energy efficiency, our innovative design delivers the same powerful performance while significantly reducing energy consumption.

Quality and Performance Combined

Quality is at the heart of our products. We select only the finest materials and components, ensuring smooth, reliable operation and superior performance. Trust in Allwin for unmatched excellence in wet grinding.

Get Your Free Quote

Products

Our Products and Services

Allwin has engineered and crafted a series of wet grinding machinery, dedicated for producing exceptional blends through advanced grinding and dispersion techniques.

Bead Mill

Bead Mill ranges from 0.3L lab units to 1000L industrial models. We offer various types: Pin, Nano, Disc, and Pin with Disc, catering to diverse grinding needs with precision and efficiency.

Super-Fine Nano Bead Mill

Engineered for ultra-fine grinding, our Nano Bead Mill excels in reducing particle sizes from 300 microns down to 100 nanometers, ideal for precise solid-liquid mixtures.

Laboratory Bead Mill

Ideal for pilot testing and laboratory research, our Laboratory Bead Mill comes in sizes from 0.3L to 5L. It's designed for small-batch production, offering precision and scalability.

Disperser/Dissolver

High-Speed Agitator Disperser excels in combining, stirring, and dispersing a range of materials, from liquids and powders to viscous substances. It's designed for efficient and uniform mixing.

Auxiliary Machinery

Our range includes Water Chillers, Grinding Media Automatic Loading Machines, Diaphragm Pumps, Filters, Filling Machines, Rotor Pumps, and Homogenizers.

Agitator/Mixing Tank

Agitator/Mixing Tank is expertly designed to blend liquids and particulate materials efficiently. It ensures uniformity and consistency in the mix, essential for quality results.

Grinding Media

Explore our beads selection – Ceramics, Zirconia, Glass, and Steel, all offering excellent impact, corrosion, and abrasion resistance for superior wet grinding performance.

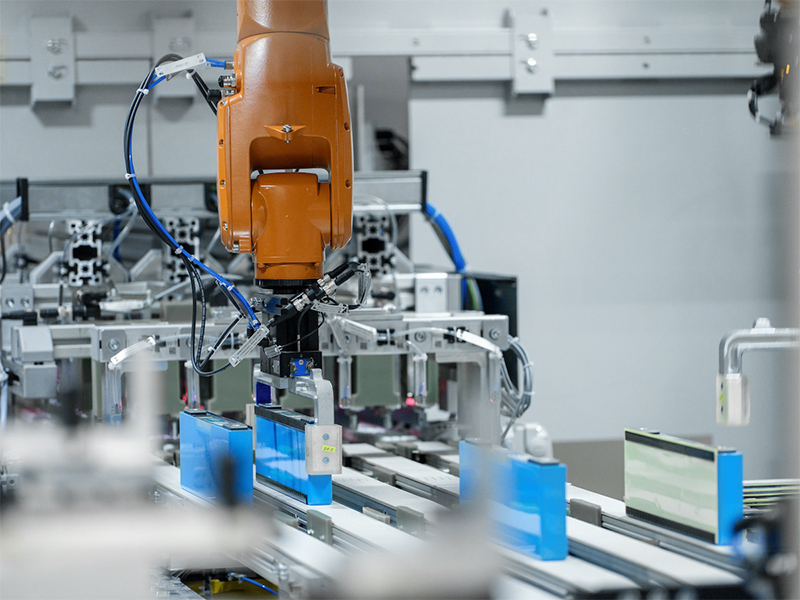

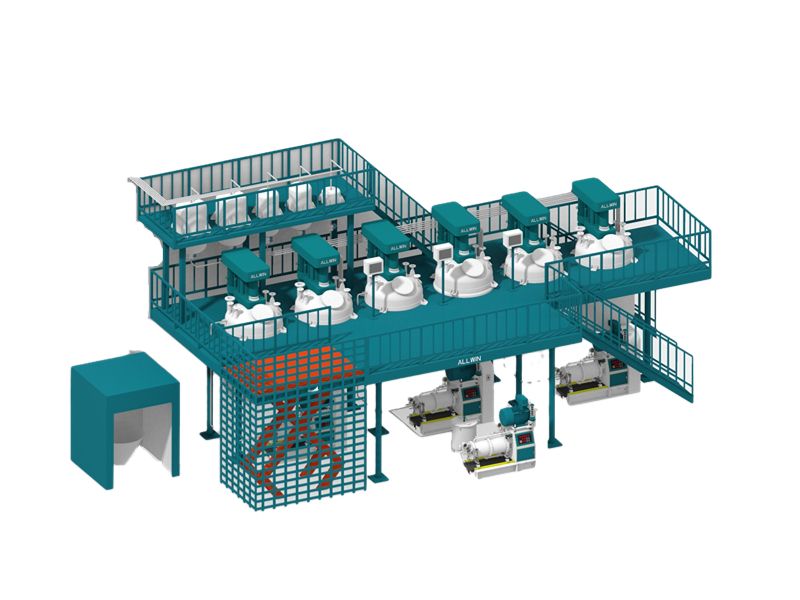

Production Line Solutions

We offer end-to-end production line solutions, encompassing workflow design, equipment supply, automation control systems, and dedicated on-site support services, ensuring seamless operation and implementation.

Want to know more about our machines?

Applications

Wet Grinding Solutions for Diverse Industries

- To meet precise industrial needs and standards, our wet grinding experts specialize in designing and manufacturing machines to enhance production capabilities.

- Applications: Battery, Ceramics, Pharmaceuticals, Food, Cosmetics, Chemicals, Paper, Inks & Paints, Coatings, MLCC/LTCC, Pesticides, and more.

Customization

Made to Fit Your Plant and Application Needs

Grinding requirements vary across industries based on particle size, impacting product composition. Our clients span from paints, inks, coatings, pesticides, lithium batteries, and food industries, among others.

Allwin delivers customized, energy-efficient wet grinding solutions. With decades of experience and an in-house R&D team, we’ve served 1,065+ customers. Our products reach multiple countries, and we’re committed to providing precise solutions for your specific particle size needs.

Machine Structure

Grinding Chamber Volumes and Materials

Mechanical & Electrical Needs

Particle Sizes and Viscosity

Capacity and Efficiency

Energy-saving Design

We Define the Quality

Our senior engineer Yongqi Wang designed the first bead mill in China and drafted industrial standards for sand mill production in China. With these technical understanding, we rise in the industry as specialists in creating wet grinding solutions that are more responsive and high-performance to any industry’s needs than our peers.

- High-quality Materials and Parts

- Well-managed Quality Inspection and Test

- Strict SOP for Production

- Allaround Test Reports

Process

Start Your Project at Allwin

From the beginning to the end, our experts will take good care of all details of your wet grinding solution.

Analyze Your Needs

Match the Right Machine

Custom Solution

Offer a Reasonable Price

Carry Out Production

Manage Quality

Commissioning

Packaging

Shipping

Clients

Our Clients

Experience excellence as our valued client.