Industry Background

Aluminum Oxide (Al₂O₃) is an essential inorganic compound, renowned for its hardness, second only to diamond. It’s extensively used in various industries such as aluminum smelting, ceramic manufacturing, electronic components, and as abrasives and chemical catalysts due to its high melting point, hardness, wear resistance, and insulating properties.

Technological Key: Bead Mill

The bead mill plays a crucial role in the processing of aluminum oxide. Allwin’s bead mill efficiently refines aluminum oxide particles through rapid rotation and multidimensional impacts, enhancing their surface area and reactivity. This process ensures uniform dispersion, prevents particle aggregation, and maintains the homogeneity of nanopowders. It offers several advantages:

- Particle Refinement: High-speed rotation and multidimensional collisions in the bead mill effectively break down and refine aluminum oxide particles, optimizing material properties by increasing surface area and reactivity.

- Uniform Dispersion: Ensures uniform distribution of aluminum oxide particles within the grinding media, preventing clumping and maintaining the consistency of nanopowders.

- Enhanced Reactivity: Treated aluminum oxide particles exhibit increased surface activity, enhancing their effectiveness in high-reactivity applications such as catalyst preparation.

- Energy Efficiency: Compared to traditional grinding equipment, the bead mill utilizes mechanical energy more efficiently, reducing energy consumption and improving energy efficiency.

- Process Control: Operators can precisely control the particle size and distribution of aluminum oxide powder by adjusting the parameters.

Practical Achievements

Over the past eight years, Allwin has completed over 700 experiments, mastered core technologies, and manufactured and sold more than 10,000 bead mills and mixers. The company’s experimental results can be precisely scaled up to production lines, providing strong data support and optimization for customers.

Client Success Stories

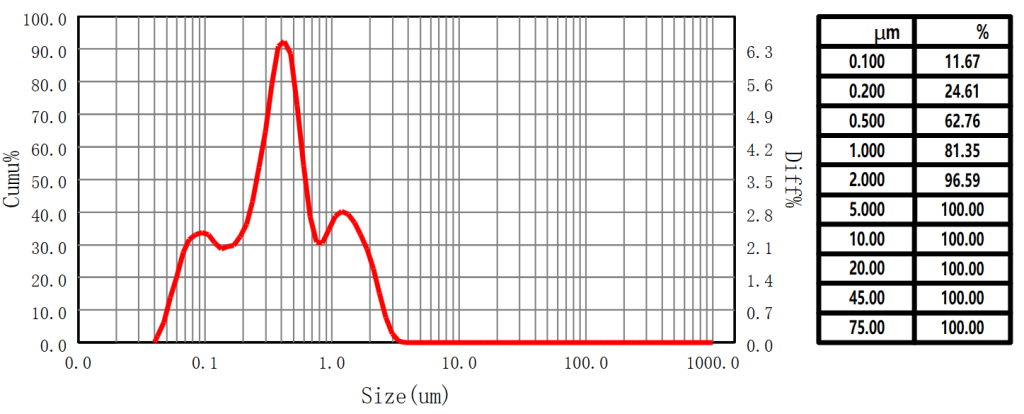

Recently, Allwin assisted three clients in completing fine grinding experiments for aluminum oxide, each time meeting the stringent fineness requirements. For instance, a client needed to grind aluminum oxide powder to a D50 range of 0.5 to 0.7 microns, and Allwin successfully achieved a D50 of 0.6 microns. Meanwhile, another client needed to grind aluminum oxide powder to a D50 range of 0.3 to 0.6 micorns, we achieved a D50 of 0.39 microns.

Recommended Product

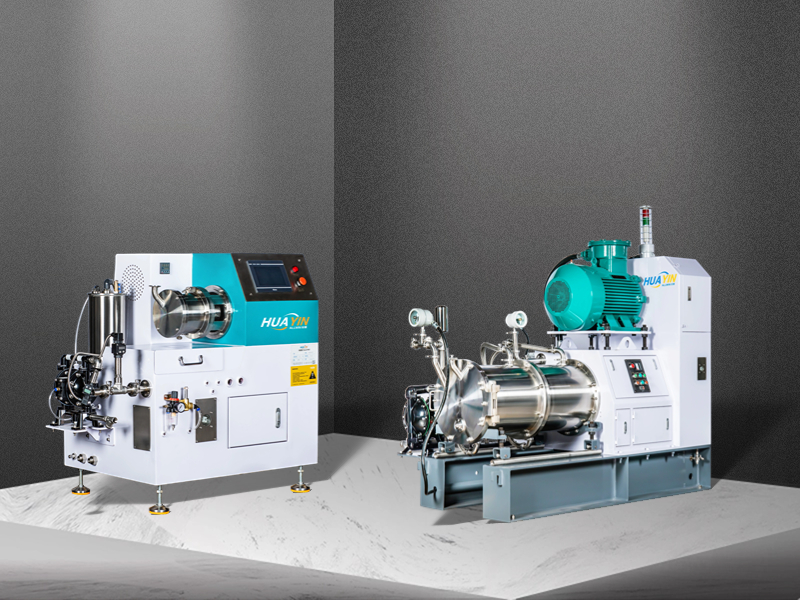

HZ Plus Nano Bead Mill

The HZ Plus series ranges from 0.5L to 1000L, accommodating various scales of processing needs for aluminum oxide, offering a flexible and efficient solution.

Contact Us

Allwin is an ISO9001:2015 certified national high-tech enterprise, specializing in bead mills, mixers, production lines, and grinding media. Click here to contact us!